Groundbreaking Developments In Spaceframe Tech

Space frame technology has witnessed profound advancements in recent years, transforming the field of various sectors and industries. Advanced technologies of this nature date back several decades, as a result of increasing demand and investment, significant progress has been made in the past few years.

One of the major breakthroughs in space frame technology is the introduction of modular components that can be easily combined. As a result, the creation and dismantling of structures becomes a straightforward process. Moreover, modular components can be easily substituted or سازه فولادی repaired. New projects are undertaken with reduced costs and increased efficiency.

Another critical advancement is the use of lively, cutting-edge materials in structures enhanced with novel materials. With the advent of new-age materials such as carbon fiber, aluminum, and other high-strength composites these space frames have become lighter, stronger, and more durable. Innovative materials facilitate the design and construction of sophisticated and intricately shaped structures.

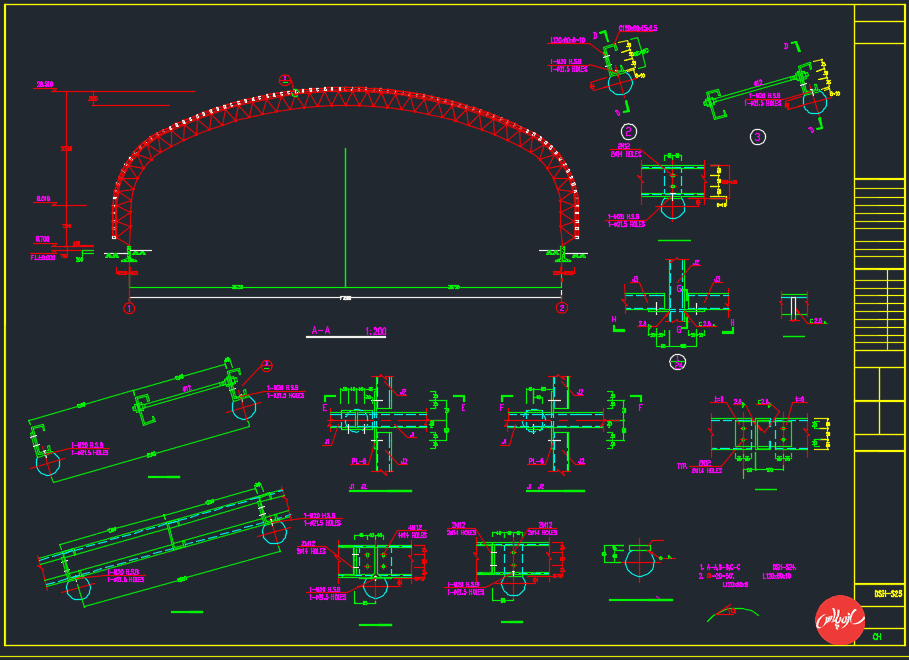

Digitalization and computer-aided design (CAD) software have dramatically impacted the space frame industry by offering designers and engineers new tools and programs that allow for precise analysis and design. Eliminating errors and optimizing structural performance, this has brought about a new era of precise engineering and streamlined production processes.

The innovations spurred in the aerospace industry have found applications in space frame construction. By adopting and adapting materials developed specifically for aircraft, significant progress has been made has taken the aerospace industry to new heights Automating processes with AI allowed humans to excel in other areas.

The increasing adoption of 3D printing technology in space frame manufacturing has also demonstrated unprecedented potential This method allows for rapid production of complex shapes and structures, significantly reducing manufacturing time and costs. Moreover, 3D printing enables the creation of intricate lattice structures that could not have been accomplished through traditional manufacturing methods.

Designed by sketchbooks.co.kr / sketchbook5 board skin

Sketchbook5, 스케치북5

Sketchbook5, 스케치북5

Sketchbook5, 스케치북5

Sketchbook5, 스케치북5