Textile Industry Innovations|

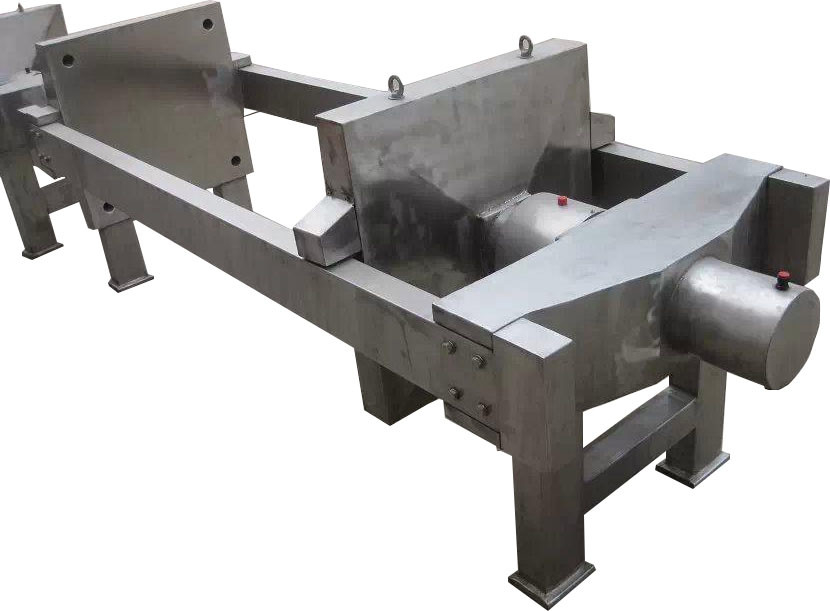

The textile industry relies heavily on various machinery to process and produce fabrics, and filter presses have been used for decades to remove liquids from various textile processes. However, recent technology developments have expanded the capabilities of filter presses, making them an increasingly important tool for textile manufacturers.

One of the most significant uses of filter presses in the textile industry is in the processing of denim, the widely used fabric used in jeans and other casual clothing. Conventional denim processing involves multiple stages of dyeing, washing, and bleaching, which can result in large amounts of harmful chemicals. Filter presses have been adapted to remove contaminants from this sludge, allowing manufacturers to recover a significant portion of the water and chemicals used in the process.

Another innovative application of filter presses is in the recovery of valuable fibers from the textile waste stream. Filter presses can be used to press fibers, making it possible to reclaim them in the production of new textiles. This approach not only reduces waste but also helps to protect raw materials and minimize the industry's environmental impact.

Filter presses are also being used to improve the quality of textiles by controlling the amount of humidity in the fabric. By applying precise pressure and vacuum to the fabric, filter presses can help to reduce moisture buildup and reduce the risk of pilling or other defects. This can lead to better quality fabrics and reduced waste in the manufacturing process.

Additionally, filter press technology is being integrated into textile production to facilitate 3D printing techniques. By providing precise control over the textile material, oil filter manufacturing machine presses are enabling the quick prototyping and production of intricate fabrics and fabrics with specific properties.

As textile manufacturers continue to investigate new ways to enhance efficiency, sustainability, and product quality, the innovative uses of filter presses are poised to become even more crucial to the industry. With the ability to recover valuable resources, improve fabric quality, and enable advanced manufacturing techniques, filter presses have the potential to revolutionize the textile industry in the years to come.

While these breakthroughs are hopeful, there is still a need for further development to fully tap the potential of filter presses in the textile industry. The melding of emerging technologies is likely to play a key role in unlocking the full potential of these valuable machines and leading to a more efficient textile industry.

Designed by sketchbooks.co.kr / sketchbook5 board skin

Sketchbook5, 스케치북5

Sketchbook5, 스케치북5

Sketchbook5, 스케치북5

Sketchbook5, 스케치북5